Right, if you’ve joined here from the Pixxel story, you’re in the right place. If you’ve just stumbled onto this piece from somewhere else, you should know that this essay is an extra appendage to a different Tigerfeathers essay on one of India’s most exciting space-tech startups - Pixxel.

This mini-piece contains many of the questions I had for the Pixxel team about how things work in space. I essentially asked them “But what does that mean?” over and over till they kicked me out of their offices. So we’ll start with some basics, before linking up with the gang at Pixxel. Should you make it to the end, you will encounter answers to questions like:

what’s a satellite?

what’s space?

what’s an orbit?

how do we get things to space?

how do you make a satellite?

why is it hard to make a hyperspectral camera?

what does ‘resolution’ mean in the context of satellite imagery?

why is it hard to make a hyperspectral satellite?

how does Pixxel make, launch, operationalise, and commercialise their satellites?

If you’ve decided to venture into the abyss with me, thank you, we’re going to try and keep a good pace here *nervous laughter*.

So, to start things off, what is a satellite?

A satellite is any object that orbits another body in space. The Moon is a natural satellite of Earth. When we talk about 'satellites', we generally refer to human-made machines of various sizes and purposes that have been artificially placed into orbit.

This kind of satellite is, at its simplest, an autonomous computer in space. This computer is typically programmed to perform some task or series of tasks. Like your laptop or smartphone, it needs power to run, a brain to process information, and a way to communicate. Unlike your devices, it also needs the armour and equipment to operate in a fiendishly harsh environment - owing to the vacuum and extreme temperatures of space - while hurtling around Earth at around 7-8 kilometers per second.

Wait, what do you mean by ‘space’?

*sigh* okay we’re going all the way in I guess.

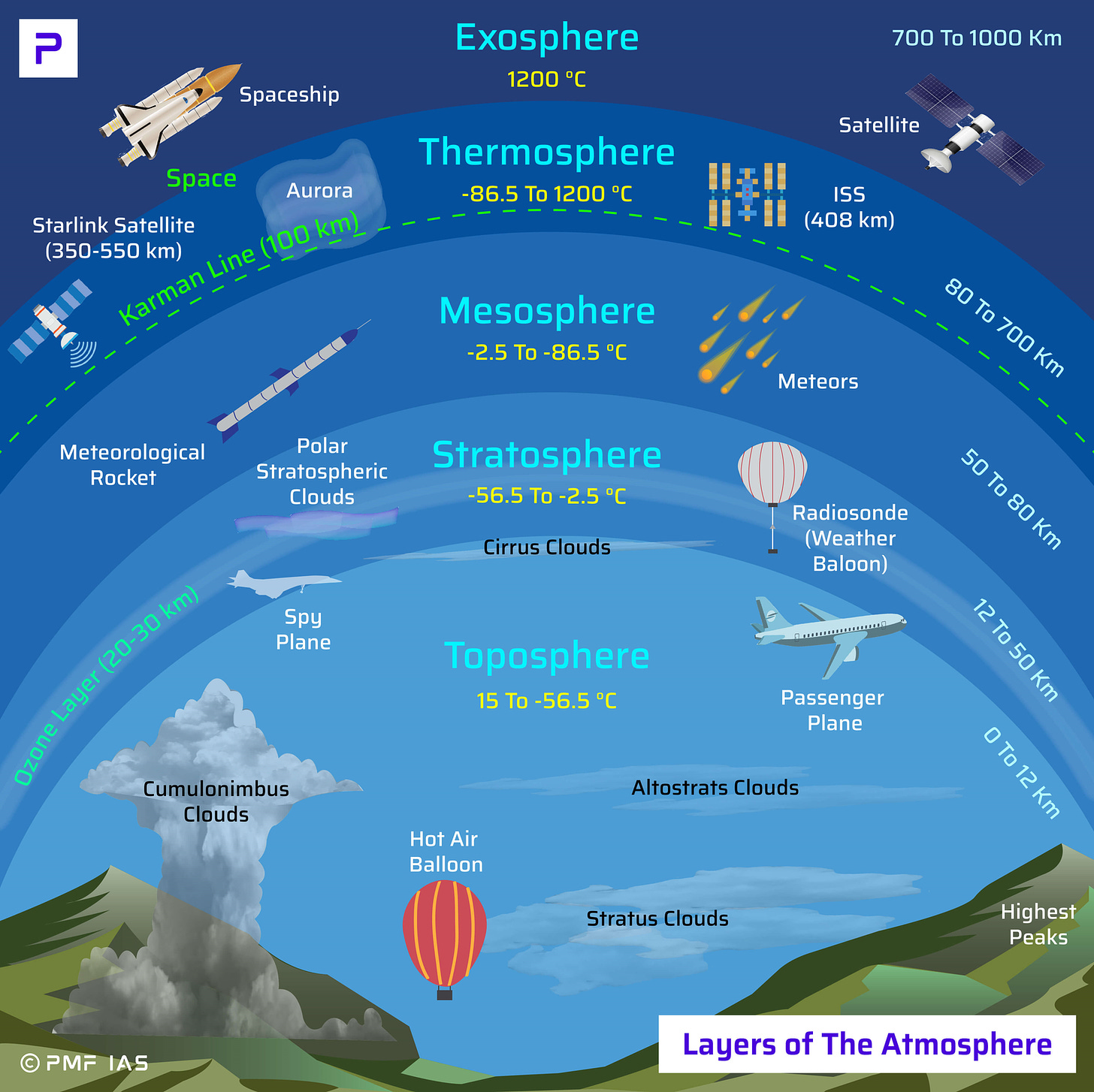

Space, technically speaking, begins where Earth's atmosphere ends - but that's not a clear line. It's more of a gradual thinning out, like how the air gets thinner as you climb a mountain, but keeps going until there's practically nothing left. Scientists needed a more precise definition, so they settled on something called the Kármán line, set at 100 kilometres above Earth's surface. This is where the air becomes so thin that traditional aircrafts can't generate enough lift to stay airborne - in other words, you need to go really fast (like, orbital velocity fast) to stay up there.

Why do we need to go that fast to stay up there? Well, because Earth's massive gravitational field means that anything we throw up will eventually come back down - unless we throw it fast enough. This is where orbits come in. An orbit is essentially a sweet spot where an object is moving so fast that Earth's gravity can't pull it all the way down. Instead of falling to Earth, it falls around it.

Come again?

Think of orbit as a perpetual state of falling around Earth. If you throw a ball, it falls in an arc before hitting the ground. Throw it faster, it goes further before falling. Throw it fast enough (about 7.8 kilometers per second), and it falls in an arc that matches Earth's curvature - meaning it keeps falling but never hits the ground. That's orbit. It's basically playing catch with gravity, except no one needs to catch the ball - it just keeps going round and round, held in its cosmic loop by the perfect balance between its speed and Earth's gravitational pull.

If we want to put an autonomous computer into the sky to keep it from either falling back down to Earth or floating away into space, ‘orbit’ is the safest place to put it. That’s where our satellites reside, in a delicate dance with gravity, zipping around Earth in their orbital paths, moving so fast that they don’t fall out of the sky, but not so fast that they escape the Earth’s gravity all together.

Orbit sounds like the place to be.

*Places to be.

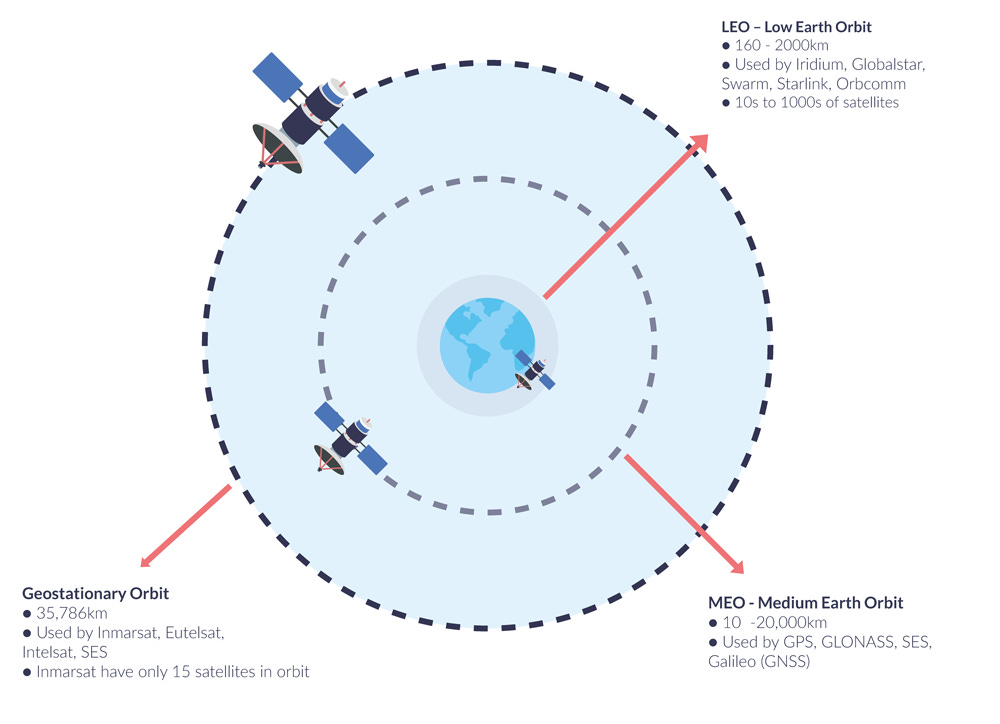

Based on the distance from Earth’s surface, we divide Earth’s orbit into a few distinct zones. These orbital zones form invisible layers around Earth. The higher the orbit, the more of Earth a satellite can see at once, but the more energy it takes to get there and the more powerful its instruments need to be to communicate or take pictures of Earth.

Different orbits serve different purposes. Most imaging satellites, including Pixxel's constellation, hang out in Low Earth Orbit (LEO), between 200-2,000 kilometres up. This is like the front row seats to Earth - close enough to take detailed pictures but high enough to avoid atmospheric drag (think of it as extremely thin air that, even hundreds of kilometres up, still creates enough friction to eventually slow satellites down and pull them back to Earth, which is why many LEO satellites have tiny thrusters to help maintain their orbit).

Navigation satellites like GPS prefer Medium Earth Orbit (MEO), around 20,000 kilometres up, where they can see more of Earth at once.

Meanwhile, TV and communication satellites usually park themselves in Geostationary Orbit (GEO) at 35,786 kilometres, where they orbit at the same speed Earth rotates, appearing to hover over the same spot - perfect for beaming signals to specific regions.

Think of it as a cosmic skyscraper: LEO is the busy ground floor with pretty garden views but more traffic, MEO is the middle floors with a good balance of view and stability, and GEO is the peaceful penthouse suite where you can see almost an entire hemisphere at once (but it costs more to get there, and even more to stay there).

You just mentioned a whole bunch of different satellites. These things have…different flavours?

There are more than 13,000 satellites in space as on July 2024. While these satellites serve many purposes, the majority of satellites in orbit today fall into two main categories - imaging satellites and communications satellites. Respectively, these satellites allow us to see things from above, or send messages across vast distances. Think of it like the Earth having eyes and ears in the sky.

Communication satellites are like TV towers or cellular towers in space. They help to broadcast and redirect electronic signals. When you're watching TV or making an international phone call, your signal is often bouncing off these satellites. Here's how it works: a signal beams up from Earth (say, from a TV station), hits the satellite, and then bounces back down to your home satellite dish. That's why you can watch the World Cup live even though it's happening on the other side of the planet. Companies like Starlink and OneWeb are taking this further, using constellations of satellites to beam internet access to remote corners of the Earth.

Imaging satellites, meanwhile, are essentially extremely sophisticated cameras in space. They're constantly photographing Earth's surface, helping us track everything from urban growth to deforestation, crop health to mineral deposits. When you open Google Maps and look at the satellite view of your neighbourhood, you're seeing images captured by these eyes in the sky.

While these are the two main categories, satellites can serve other specialised purposes too. Navigation satellites (like GPS) help you find your way around. Weather satellites track storm systems and climate patterns. Scientific satellites study everything from solar flares to distant galaxies. Startups in the New Space age are taking this one step further, envisioning the use of satellites as mirrors to reflect the sun’s rays onto Earth, or as research labs to develop pharmaceutical drugs in the microgravity of space. It’s getting wild out there…

…but don’t worry about that for now. For all intents and purposes, communication and imaging take up the bulk of our space infrastructure, forming the backbone of our increasingly space-dependent civilisation.

Sweet. So how do we actually get satellites into space?

Good question.

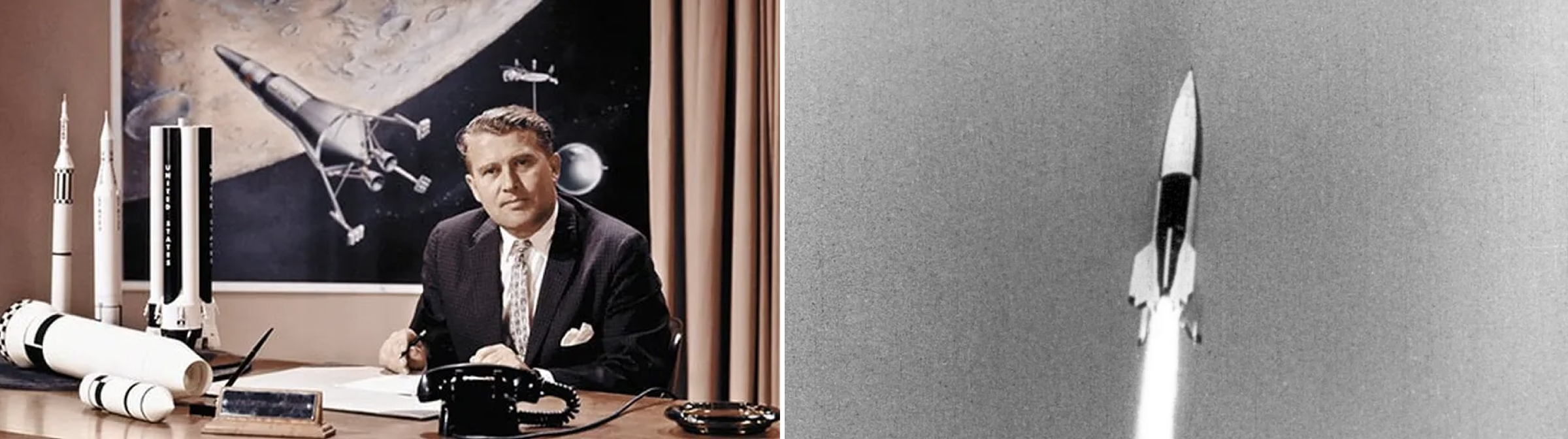

Getting satellites into space requires rockets, and the modern story of rocketry begins in an unlikely place - Nazi Germany.

During World War II, Wernher von Braun led the development of the V-2, the world's first long-range ballistic missile. The V-2 was a terror weapon that devastated London during WWII, but it also made history as the first human-made object to cross the Kármán line. Later, captured and repurposed V-2s launched by American scientists would take the first photographs of Earth from space in 1946.

After the war, the US and USSR frantically sought to capture the best German scientists (and their revolutionary rocket designs) in what was called 'Operation Paperclip', much like two football teams would hustle to snap up the best free agents after the transfer window closed. The two Cold War superpowers understood that whoever mastered rocketry would not only have military superiority, but also first dibs on a more tantalising prize - space.

As it turned out, the same principles of physics that once delivered bombs into the sky could be repurposed to deliver a more diverse selection of cargo to space, including satellites, space telescopes, and even human-carrying spacecraft. The assigning of new teams for some of Nazi Germany’s best scientific minds effectively sparked the beginning of the Space Race. von Braun ended up working for NASA. He would go on to become the chief architect of NASA's Saturn V rocket - the mighty launcher that would eventually carry humans to the Moon during the Apollo program.

At their core, rockets are basically controlled explosions pointed in one direction. They work on a principle that Newton figured out centuries ago: for every action, there's an equal and opposite reaction. When a rocket burns fuel, it creates hot gases that shoot out of its engines at extremely high speeds. This violent expulsion of gas in one direction pushes the rocket in the opposite direction - the same way releasing an untied balloon sends it zooming around the room as air expels in the other direction. The key innovation of the V-2, which continues in modern rockets, was the ability to control this explosive force and sustain it long enough to reach unprecedented heights.

When missile technology was repurposed for space, engineers essentially took this same principle but refined it: instead of using rockets to lob warheads at targets on Earth, they calculated exactly how much power and speed would be needed to "miss" Earth entirely - sending these ‘missiles’ into orbit instead. The same technology that once delivered bombs could now theoretically deliver a bunch of non-violent cargo into space, just by positioning rockets at the right angle and giving them enough thrust to get to leave Earth entirely.

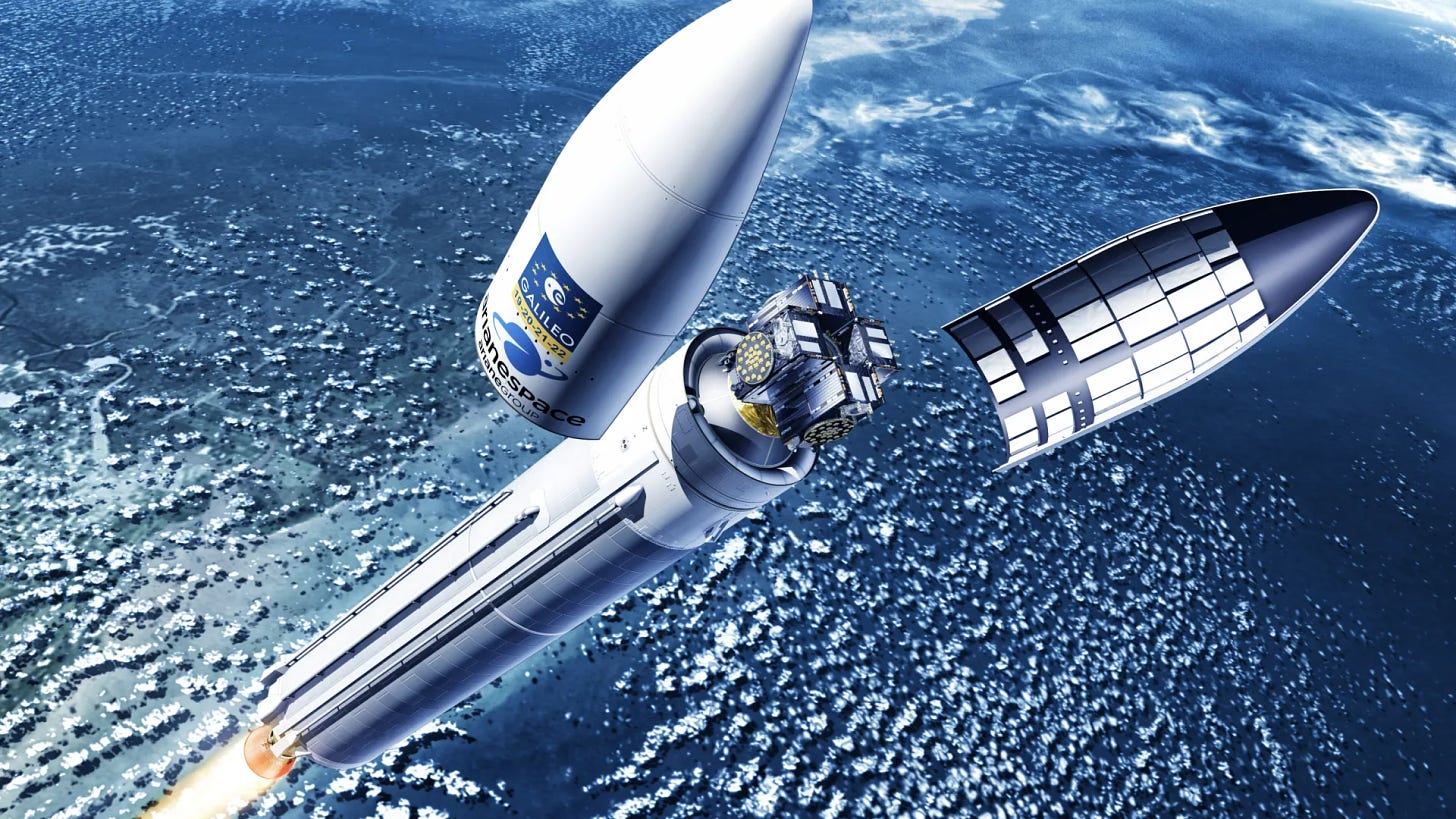

That’s how satellites get into space, strapped to the top of rockets, or, to be less crass - carefully secured inside a protective shell (called a fairing) at the nose of the rocket.

This protective casing shields the delicate satellite from the intense forces of launch - the violent vibrations, crushing air pressure, and extreme heat generated as the rocket blasts through Earth's atmosphere at thousands of miles per hour. Once the rocket punches through the atmosphere into the relative calm of space, the fairing splits open like a clamshell and falls away, exposing the satellite for its eventual deployment into orbit.

Sometimes multiple satellites share the ride, stacked and secured tightly together like a game of tetris. The satellites (or satellite) are mounted on special deployment mechanisms - kind of like fancy spring-loaded platforms - that will "push" them into space at exactly the right moment.

That’s how satellites get to space.

Sounds simple enough.

Well…it’s little trickier in practice.

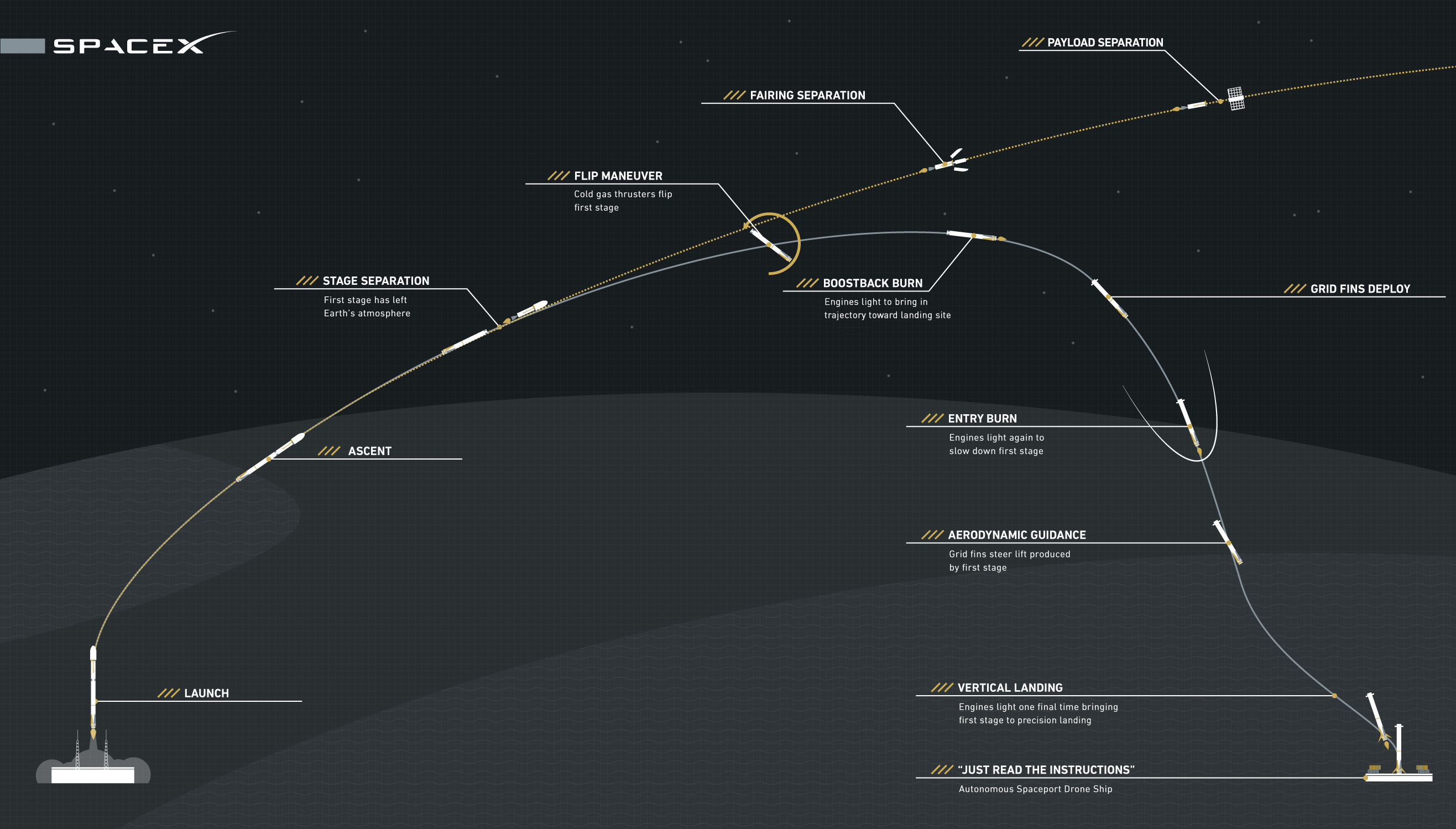

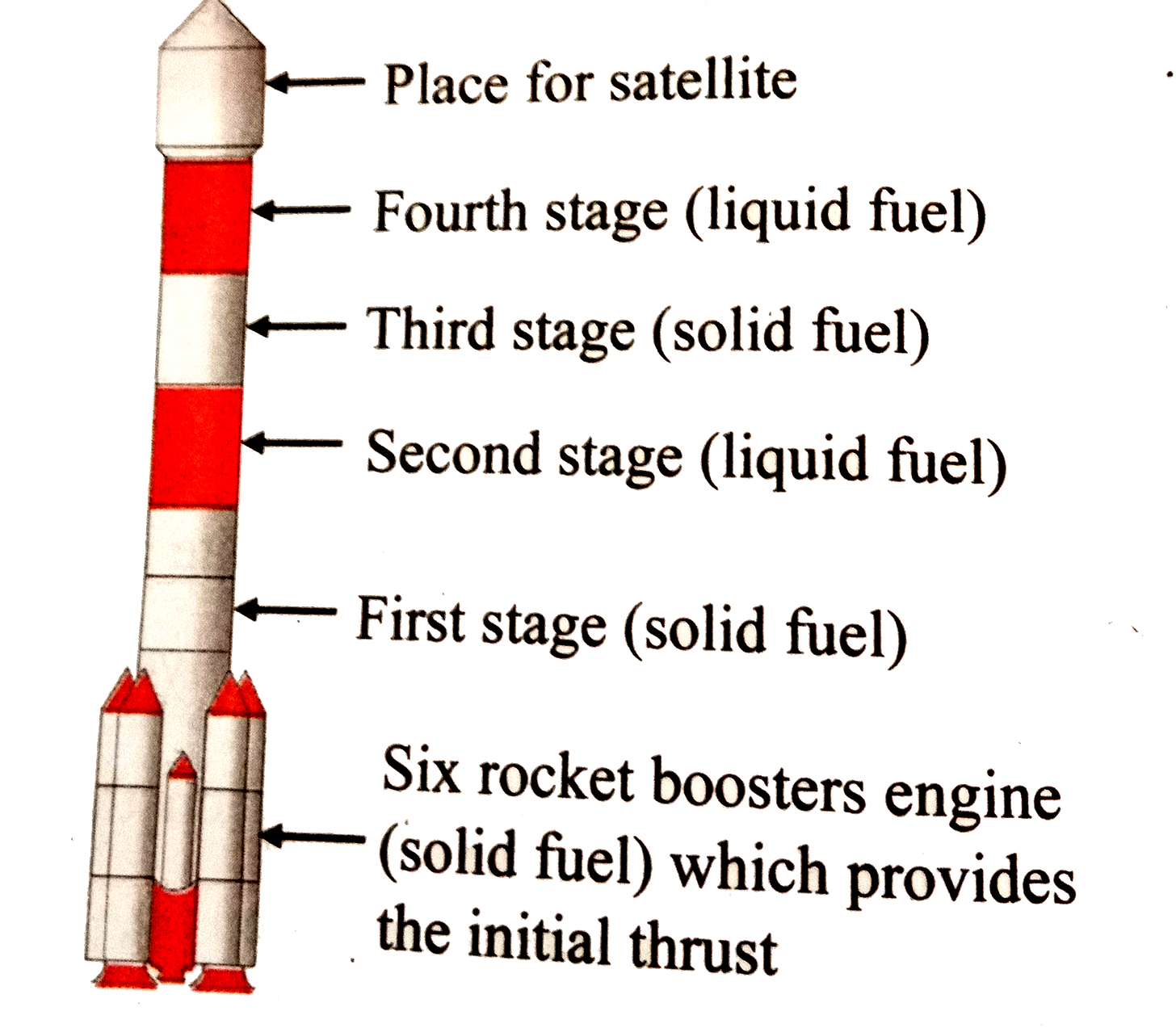

The journey to orbit happens in stages. Modern rockets are essentially a stack of separate rockets working in sequence.

In the case of SpaceX’s Falcon 9 rocket (a two-stage rocket), the first stage (called the booster) does the heavy lifting, burning through tons of fuel to push through the thick lower atmosphere. Once it runs out of fuel, it detaches and falls away (in SpaceX's case, it then lands itself for reuse). The second stage then ignites, carrying the payload (i.e. the satellites) to its intended orbit. At just the right moment - when the rocket has reached the correct altitude and speed - those deployment mechanisms activate, gently pushing the satellites out into space.

But a satellite's journey isn't over once it leaves the rocket. Typically each satellite has small thrusters and a sophisticated navigation system. Over the next few days or weeks (or months), it uses these to fine-tune its orbit, unfurl its solar panels for power, and orient itself correctly. This process, called the Launch and Early Orbit Phase (LEOP), is carefully monitored by the satellite’s owners/operators on the ground. Once the satellite has properly deployed, it can begin its actual mission, whether that's taking pictures of Earth or beaming communications signals or collecting data etc.

Over the last 80ish years, humans have nailed this complex choreography of controlled explosions, precise mechanics, and careful navigation. Today, companies like SpaceX have made this process so routine that they launch rockets (and satellites) into space almost twice a week, though it's worth remembering that every launch is still a remarkable feat of engineering. We're essentially throwing computers into space at 17,000 miles per hour and expecting them to work perfectly. Wild when you think about it.

Phew. Okay. So a satellite is basically a little robot that hitches a rides to space at the top of a ballistic missile, and just kinda hops off once it reaches its destination?

Pretty much.

Sweet. Can we get back to Pixxel now?

I thought you’d never ask.

So Pixxel, I assume, is making imaging satellites, right?

Indeed. Their satellites are equipped with hyperspectral cameras that capture images of the Earth with unprecedented spectral resolution.

Right. Going back to our story, the team decided to make these satellites in-house after the first failure to launch, right?

Yup.

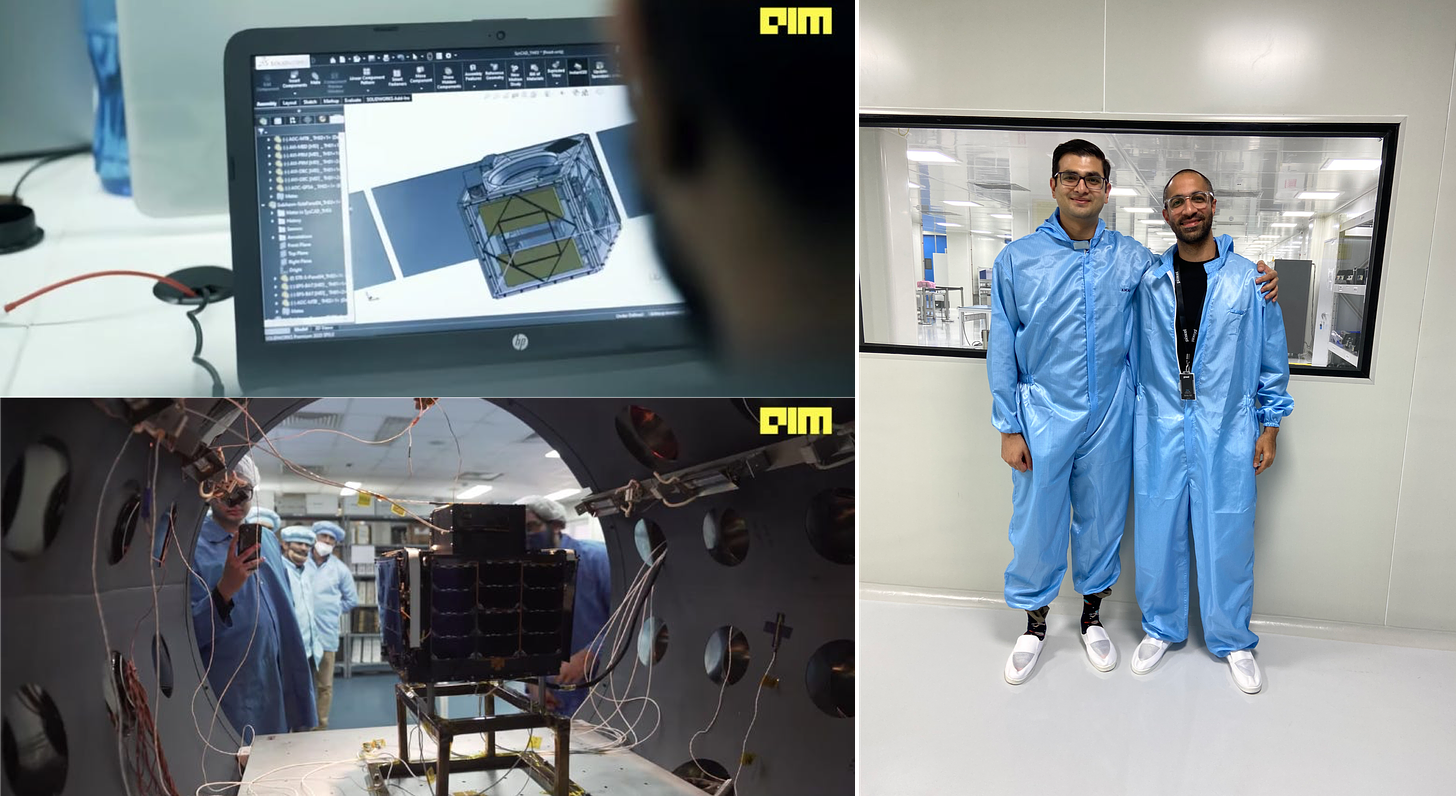

So what does ‘making your own satellite’ entail exactly?

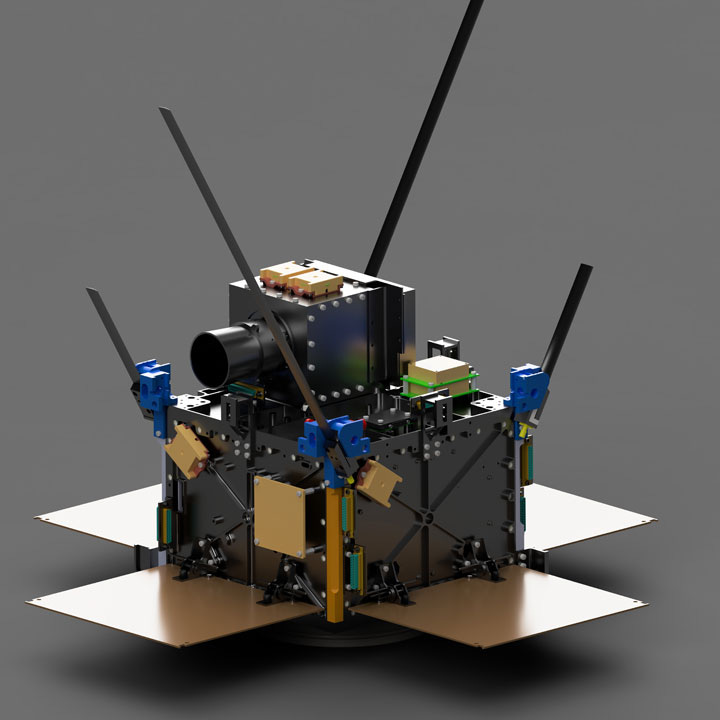

“When we set out to build a satellite, we don't start with the hardware - we start with a methodical process called the Mission Concept Review,” says Awais. “This is where we define our primary objectives, which are originally dictated by the requirements and specifications of our customers. In Pixxel's case, the mission requirement is to capture hyperspectral images at 5-meter resolution, providing 24-hour revisit capability to any terrestrial point on Earth, and fitting a sophisticated imaging payload (i.e. the camera) into a compact 1m x 1m form-factor (that affects the dimensions, weight and size of the satellite).”

These high-level goals cascade into increasingly specific technical requirements. For instance, if you want 5-meter resolution images from space (where each pixel in the image represents a 5m x 5m parcel of land), physics dictates how big your camera needs to be. The size of the camera then determines how large your satellite must be to carry it. This in turn affects how much power you'll need, which determines the size of your solar panels and batteries. Every decision is interconnected, creating a complex web of trade-offs that engineers must carefully balance.

So a bigger camera might give better images, but it also means a heavier satellite - and every extra kilogram costs thousands of dollars more to launch. Want more frequent coverage of Earth? You'll need more satellites in your constellation. Want your satellite to last longer in orbit? You'll need more fuel for propulsion, which again means more weight and more cost. As Kshitij explains, "Space engineering is just trade-offs. You have to figure out which ones are worth making for your own mission.”

This design process, borrowed from the philosophy of space agencies like NASA, is based on every sub-system working in perfect harmony. It's not enough for each component to work well individually; they need to work together as a single, reliable spacecraft that can operate autonomously for years in an unforgiving environment.

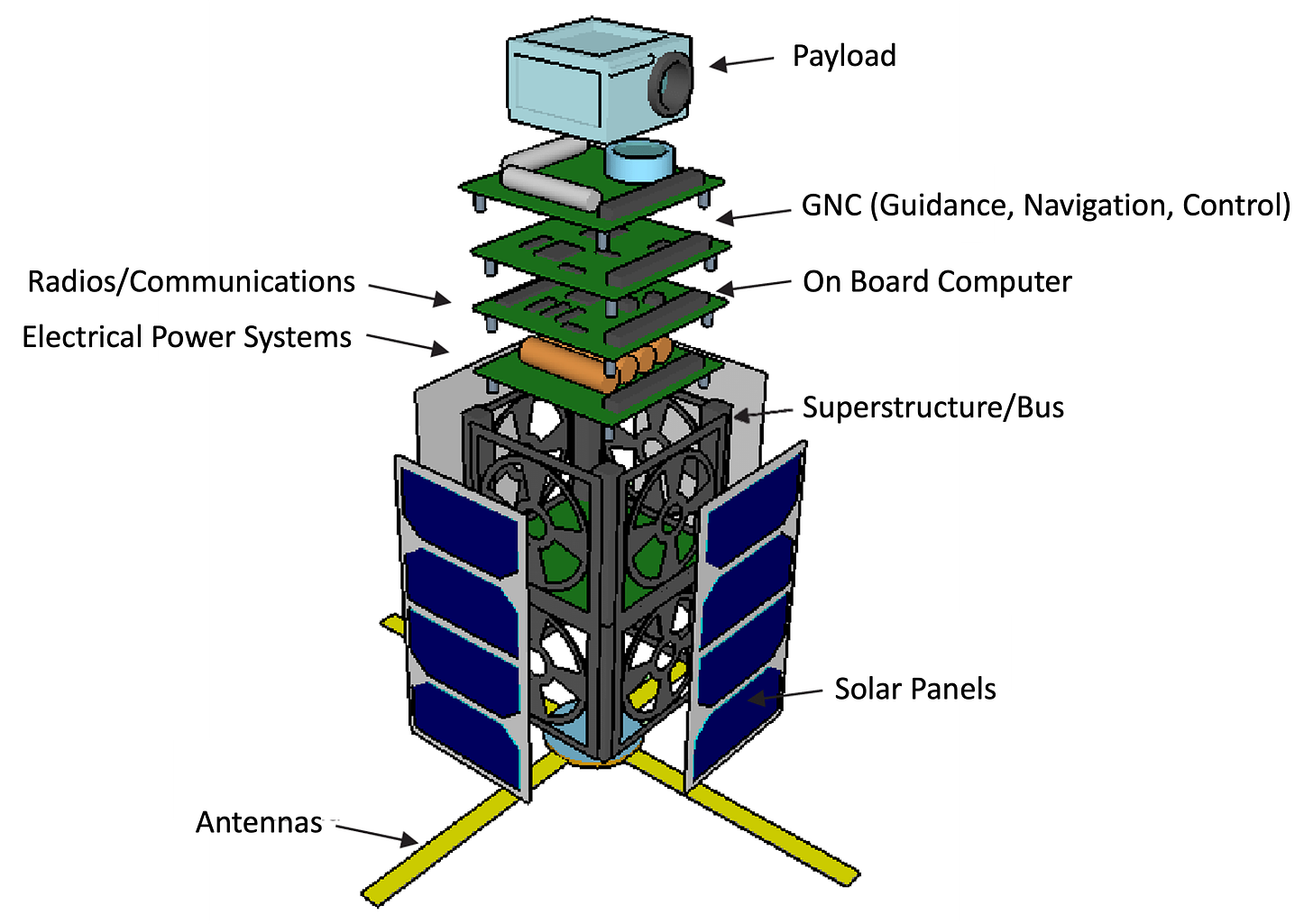

Okay, so satellites are a game of trade-offs between different sub-systems and requirements. Which sub-systems are involved exactly?

A satellite is essentially built around its purpose. It consists of two main parts: the "bus" (i.e. the body of the satellite which provides all the core functions like power, navigation, and temperature control); and the "payload" (in this case, the hyperspectral camera) which performs the satellite's actual mission. As Teja from Pixxel explains, "A satellite is defined by its payload - that's the thing the satellite is carrying. That’s its purpose of existence. In our case, it's a hyperspectral camera. Every other component in the satellite exists to ensure that this camera operates as intended at the right time."

Think of it as a sophisticated support system for one very demanding piece of equipment. The camera's requirements dictate everything: how big the satellite needs to be, how much power it needs, how stable it must remain, even what orbit it should fly in. It's like building a precision watch around its chronograph - thousands of intricate parts working in concert to support one critical function.

This support system breaks down into several critical subsystems:

Controls (AOCS/GNC): This is the satellite's balance system, keeping it steady enough to capture sharp images while hurtling through space at 7 kilometers per second. Imagine trying to take a clear photo while running - now multiply that challenge by about a thousand.

Power Systems: Solar panels and batteries to keep everything running. The sizing is precise - too small and your camera won't work when needed, too large and you're wasting precious weight and space.

Communications: Antennas and radios to receive commands and beam data back to Earth. This becomes especially crucial with hyperspectral imaging, which generates massive amounts of data that needs to be transmitted quickly during brief passes over ground stations.

Thermal Control: Space is an environment of extreme temperatures. As Teja notes, "Batteries and cameras are particularly sensitive to temperature. We need precise thermal control systems - sensors, heaters, insulators - to keep everything operational."

Structure: The physical framework holding everything together, designed to survive the violence of launch while being as light as possible. Pixxel uses aluminium and honeycomb panels, carefully designed to protect the delicate instruments within.

For Pixxel, the camera (i..e the payload) isn't just another component - it's their secret sauce. "Most companies can build satellites," Kshitij explains, "but the hyperspectral camera is what separates us. We design and build these cameras ourselves, optimising the entire satellite around them. When others compromise on camera capability to fit standardised satellite buses, we do the opposite - we build our satellites to maximise what our cameras can do."

This camera-first approach comes with significant challenges…

Which is?

…that hyperspectral cameras are notoriously difficult to build and operate in space.

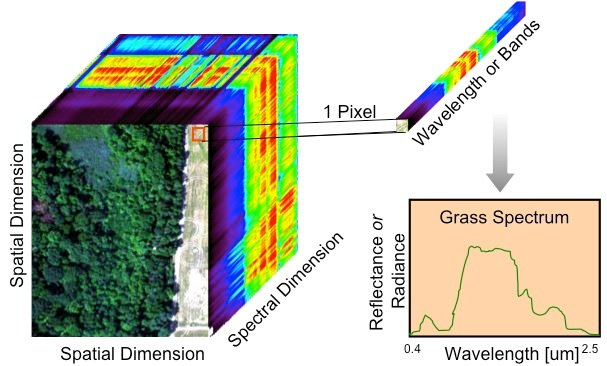

As a reminder, a hyperspectral camera is one that captures light across hundreds of different wavelengths simultaneously. Unlike a regular camera that records just three colours (red, green, blue), or even a multispectral camera that might capture 10-20 bands, a hyperspectral camera slices the electromagnetic spectrum into hundreds of narrow, continuous bands.

Each pixel in a hyperspectral image contains detailed information about how that specific point reflects or absorbs light across these wavelengths. Because different materials interact with light in unique ways, this rich spectral data allows us to identify the chemical composition of whatever we're looking at - from mineral deposits to crop diseases to atmospheric pollutants.

So where our eyes (and regular cameras) just see "green" when looking at a forest, a hyperspectral camera breaks down that green into hundreds of distinct spectral signatures.

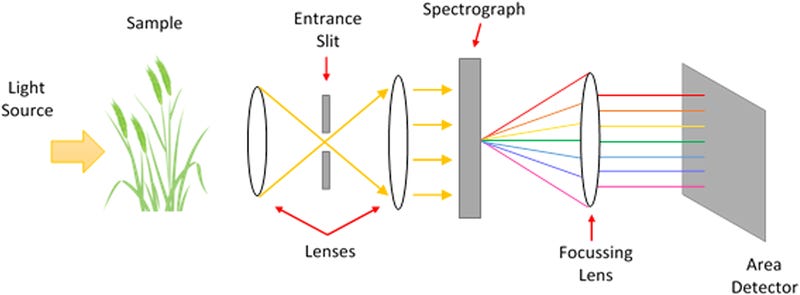

A hyperspectral camera is an elegant feat of optical engineering. At its heart is a sophisticated system of mirrors, lenses, and sensors working in perfect harmony.

Light enters through the aperture and encounters a series of precise optical elements that split it into its constituent wavelengths, much like a prism but with far greater precision. These separated wavelengths are then directed onto highly sensitive detector arrays that can capture hundreds of distinct spectral bands simultaneously, creating what's essentially a spectral fingerprint for every pixel in the image.

This ability to see the chemical makeup of things from a distance is what makes hyperspectral imaging so powerful - it can tell the difference between healthy and stressed plants, identify specific minerals in rock formations, or detect gas leaks that are invisible to the naked eye.

For the technology to work, the entire system must be perfectly aligned - we're talking micrometer-level precision - to ensure each wavelength hits its target correctly. Even on Earth, building such a camera requires extraordinary attention to detail and state-of-the-art manufacturing capabilities. You can just imagine, then, that in space…

It’s hard AF.

What makes it harder, is that while most competing satellite companies buy their cameras made-to-order from external vendors, Pixxel designs its own down to the tiniest detail. "The camera is what makes the satellite the satellite," explains Awais. "It's the most involved and challenging piece of the puzzle."

Building a hyperspectral camera for space is an exercise in managing extremes. As mentioned above, the optics - the mirrors, lenses, and sensors - must be aligned with micrometer precision. That's challenging enough on Earth, but now imagine maintaining that precision as temperatures swing from -20°C to +60°C. The slightest thermal expansion can throw everything off. Add to this the violent vibrations of launch, where rocket engines generate enough force to potentially shift these delicate alignments. "If a mirror is off by even a millimetre," Kshitij notes, "the camera becomes useless - and you can't fix it in space."

Then there's the speed challenge. Unlike regular cameras that capture three bands of light (red, green, blue), Pixxel's Firefly satellites will capture over 250 spectral bands. Think of it like taking 250 photos of the same scene simultaneously, each one capturing a different slice of the electromagnetic spectrum. Now do this while your camera is zooming over Earth at almost 8 kilometres per second. "The speed at which we need to read and distinguish between different wavelengths is the real challenge," says Manas. "With regular RGB imaging, you can read pixels much faster. But we're processing 250 times more information."

So Pixxel makes these all in-house?

While Pixxel conceptualises and designs these complex cameras themselves, they work with specialised manufacturers under exclusive contracts for the actual production. They own the intellectual property and the design - a strategic decision that gives them control over their most crucial technology. This approach has allowed them to push the boundaries of what's possible.

Their latest cameras will offer 5-meter resolution across hundreds of spectral bands, a capability that puts them at the forefront of commercial hyperspectral imaging.

"We could have bought satellites from elsewhere," Awais explains, "but the hyperspectral part is what makes us special. We design the cameras ourselves, and we own the IP. We've gone from 30-meter resolution to 10, and now to 5. We can go to 1-meter tomorrow if we want. Even Planet Labs gets their hyperspectral technology from JPL [NASA’s Jet Propulsion Lab] - and JPL isn't going to upgrade that in a few months. Our team can iterate fast. Controlling the camera supply chain was critical."

Quick question - what do you mean when you say ‘resolution’?

When it comes to satellite imagery, 'resolution' isn't just about how crisp a picture looks. There are actually three types of resolution in question:

spatial resolution (how clearly you can see something or how detailed the image is) - for instance, in ‘1-meter resolution’ imagery, each pixel in an image corresponds to a 1m x 1m square of Earth

temporal resolution (how frequently you can photograph the same spot),

and spectral resolution (how many different wavelengths of light you can capture).

By 2019, different companies had solved different pieces of this puzzle. Maxar had pushed spatial resolution down to 30cm, meaning you could distinguish objects on Earth that were just a foot apart. Planet Labs revolutionised temporal resolution, launching hundreds of small satellites to photograph the entire Earth daily, rather than waiting weeks between images. But spectral resolution remained a gap - while government satellites and drones could capture some spectral data, no commercial company was delivering high-quality hyperspectral imagery from space.

Previous hyperspectral missions faced harsh trade-offs: NASA's early efforts achieved excellent spectral detail but could only manage 30-meter spatial resolution (meaning each pixel represented a 30m x 30m area - no good for commercial use cases), while others sacrificed image quality for faster revisit times. Historically you’d have needed a fleet of giant, billion dollar satellites with large cameras to achieve the kind of commercial scale hyperspectral resolution that had eluded early hyperspectral satellite missions.

Pixxel's engineering breakthrough was in avoiding these compromises. Their future satellites will achieve 5-meter spatial resolution and daily revisits while capturing over 250 spectral bands - doing with six satellites what others need forty to achieve, thanks to their custom-designed cameras and wide field of view.

Ok you can go on.

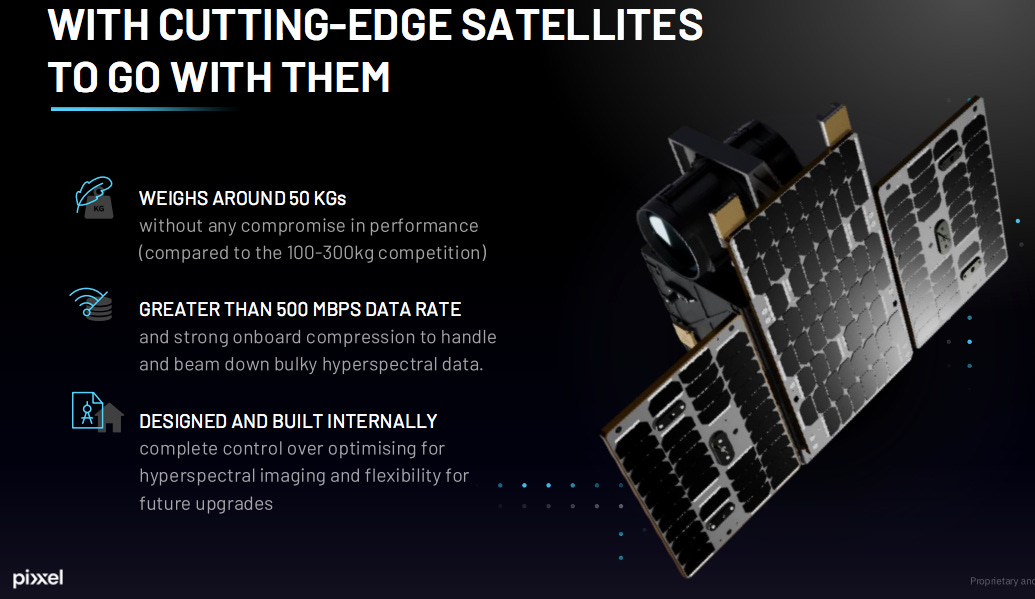

Anyway, Pixxel’s focus on the camera has another advantage: it forces them to build better satellites. Each satellite must be exceptionally stable to allow the camera to capture clear images. The power systems must be robust enough to handle the massive data processing requirements. The communication systems must be powerful enough to beam down enormous amounts of spectral data. In optimising their satellites around their cameras, Pixxel has had to push the boundaries of what small satellites can do.

While satellite buses have become (almost) commoditised technology - available off-the-shelf from dozens of manufacturers around the world - Pixxel still chooses to build their own. "We can build the satellite to our exact constraints," Teja explains. “We don’t have to make compromises on the design or capability of our camera to fit some standardised satellite model.” Instead, they build their entire spacecraft around maximising the potential and effectiveness of their hyperspectral technology.

It’s another counterintuitive move. This full-stack approach means Pixxel have to do a lot more heavy-lifting behind the scenes - investing time, money and energy in building their own satellite buses (vs competitors that only focus on the camera, ensuring a quicker route to market). But they see vertical integration as being key to gaining a long-term strategic foothold over the entire imaging value chain. Another plus - they gain a deeper understanding of the costs and benefits of the space-tech value chain, an outcome key to expanding their commercial canvas in the years to come.

So how much time, money, and energy does it take them to build satellites now?

Pixxel’s new 30,000-ft ‘Megapixxel’ facility in Bangalore is India’s first private satellite-manufacturing plant. It’s where the designing, integration and testing of their satellites takes place.

The design phase for their satellites can last upto 8-9 months. Once components arrive (some rare materials can take up to 18 months to source), assembly begins in their sophisticated ‘clean rooms’, where the air is kept free from dust particles and other contaminants. Each satellite takes roughly a month to assemble once all the parts are ready, and another month to go through comprehensive testing to ensure space-readiness.

Their new facility can handle the production of upto 25 satellites simultaneously. Their upcoming constellation - including their 50-kg Fireflies and 100-kg Honeybees - cost between “low single-digit millions to 10 million dollars each to build and launch”. With an idealised turnaround time of 4-6 months from assembly to shipping, the facility could theoretically produce up to 75 satellites per year when fully optimised.

The Megapixxel facility is unprecedented for a private company in India. The facility houses everything under one roof: electronics labs for prototyping, environmental testing chambers, camera integration labs, and a dedicated mission control room. "The facility enables us to control the entire flow of building satellites," explains Awais. "It's cheaper, faster, more efficient - and most importantly, we're not dependent on anyone else for timelines. We can iterate faster without external dependencies."

Given the already shrinking costs of electronic components and sensors that have exponentially brought down the costs of making satellites, Pixxel has been able to generate a 5-10x cost advantage over their competitors due to a number of factors.

"Over the last four decades, ISRO has built up an ecosystem of supply chain providers," Kshitij explains. "We use the same vendors as secondary buyers, which keeps costs lower than North America or Europe." When you start with the ‘India Advantage’ of relatively cheaper labour and manufacturing costs, and you add smart engineering choices and their decision to vertically integrate production, you get a a cost structure that's hard for competitors to match.

Right. So that’s the design and production stuff covered. What else do we need to know?

Before a satellite heads to space, it needs to prove it can survive the journey. Each satellite undergoes a month of rigorous testing - from thermal vacuum chambers that simulate the extreme temperatures of space to vibration tables that replicate the violent shaking of launch. Think of it as a space boot-camp, where only the toughest survive.

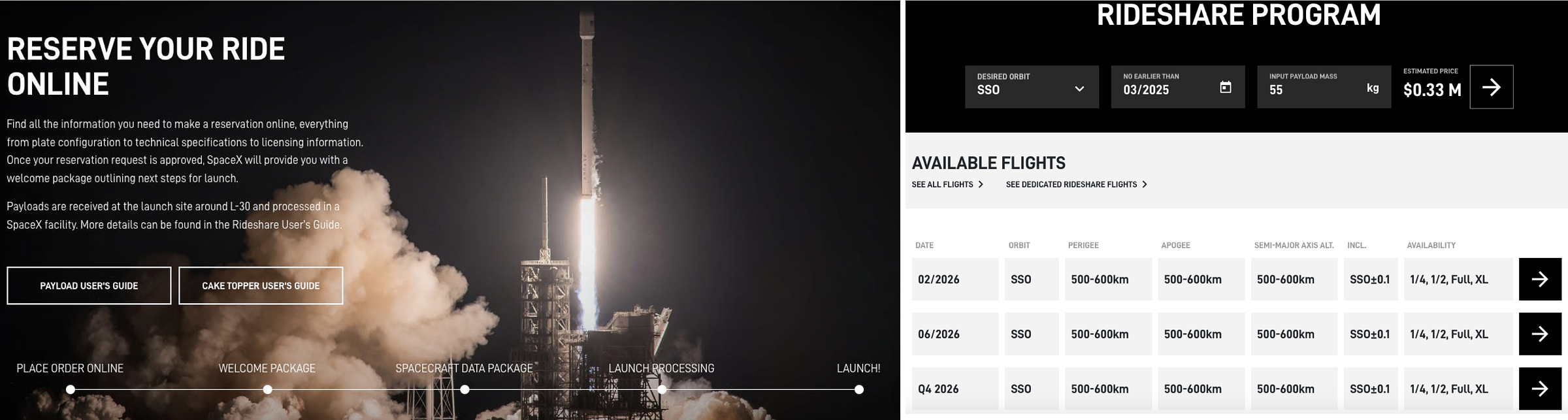

Then comes the complex choreography of actually getting to space. Launch preparations begin 6-8 months before liftoff, starting with booking a spot on a rocket - essentially reserving a seat on a very expensive, very explosive bus. While SpaceX might offer the lowest price per kilogram (<$3,000 compared to legacy rates of ~$55,000), the decision isn't that simple.

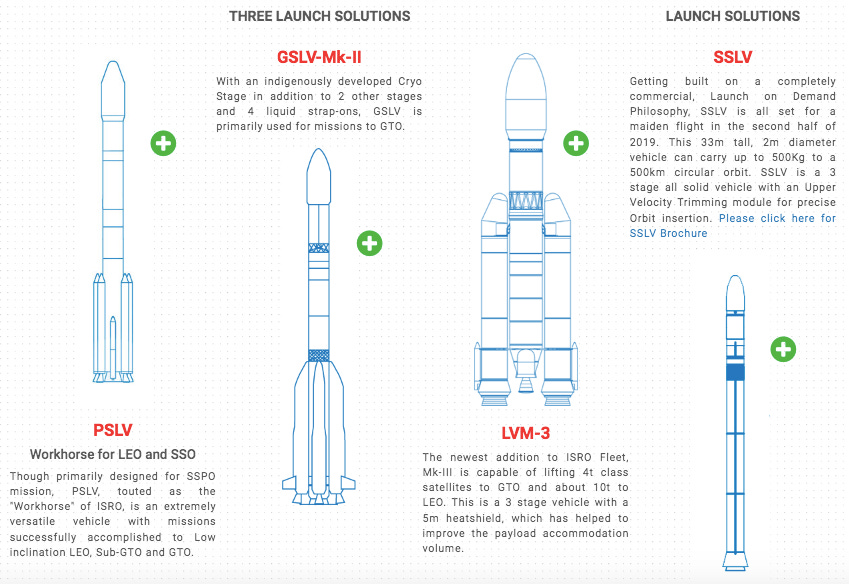

The choice of launch provider isn't just about cost. Pixxel has to consider factors like orbital parameters (they need their satellites at 550-600 kilometres in a ‘sun-synchronous orbit’); the launch site's location (which affects logistics and costs); the timelines of the rocket launch (is there a rocket launch scheduled around the time they’re ready to ship?); volume constraints (does that rocket have enough space available for their satellites?), and several others in addition to the budget.

SpaceX operates almost like a cosmic bus service. Their orbits are typically dictated by their primary payload operator (eg: if a company or government books out all or the majority of available capacity, they get first dibs to prescribe the destination orbit), or the requirements of SpaceX’s own Starlink internet satellites (which take up a significant chunk of SpaceX’s launch quota). This means that smaller satellites like Pixxel's are effectively hitchhikers, having to work with whatever orbit is available.

It’s why, despite SpaceX’s bottom-of-the-barrel rates, it can occasionally make more economic sense to pay 20% more for a dedicated small satellite launch vehicle (eg: from the likes of ISRO or the European Space Agency) that can put you exactly where you need to be. "If you have to build your own propulsion systems and use your own fuel to reach your desired orbit from SpaceX's ‘drop-off’ point - adding time and costs to operationalising your satellite in space - those savings in launch expenses can quickly evaporate," explains Teja.

So what are my options if I want to book a launch today?

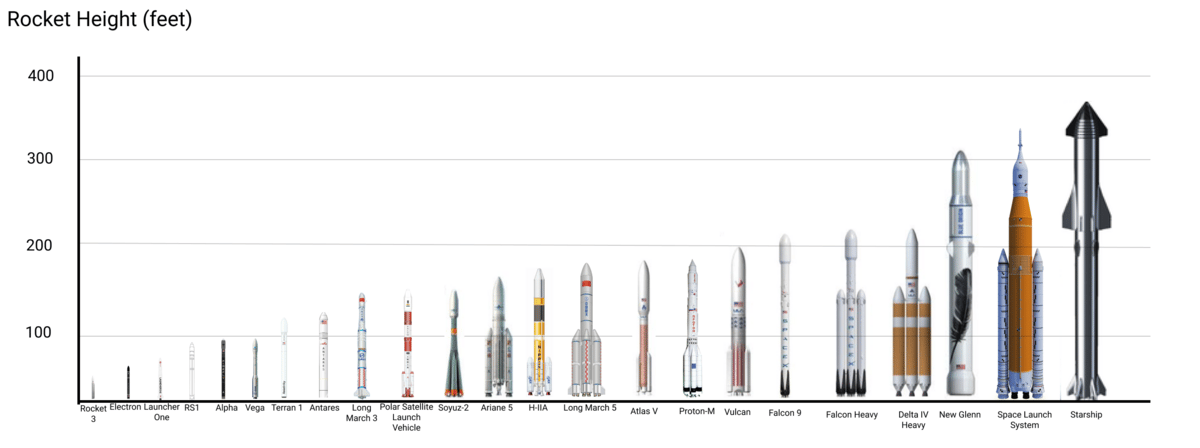

Historically, getting something to space meant dealing with a small coterie of government space agencies. The United States, Russia, Europe (through ESA), China, Japan, and India were the only players with reliable launch facilities (today there are a few more countries with a varying degree of launch capabilities). Launches were expensive, infrequent, and primarily served government missions. A ticket to space could cost upwards of $54,500 per kilogram (on the now-defunct NASA Space Shuttle), so the cost of building and launching a satellite could mean anything from $200 million to $1 billion.

Today geopolitical factors and economic factors have severely limited the options on the national launch front. For instance, after the Russia-Ukraine war, the viability of booking Roscosmos’(Russia’s) trusty Soyuz rocket has diminished for most countries allied with Ukraine. In the US as well, NASA decommissioned its long-tenured Space Shuttle in 2011, no longer believing it could meet either the technical or cost benchmarks required to best fulfil its role. For now, The US effectively relies on private companies (mainly SpaceX, and to a lesser extent Boeing and Lockheed Martin), to carry out all its research and defence missions to space.

As we’ve covered a few times now, SpaceX is the undisputed king of the commercial launch market today. But Musk & Co’s pioneering efforts have inspired other entrepreneurs to enter the launch arena, particularly to ferry ‘small satellites’ to space. Globally, this includes companies like Rocket Lab and Firefly Aerospace.

In India, venture-funded startups like Skyroot Aerospace and AgniKul Cosmos are leading the charge, experimenting with modular designs and 3D printing to manufacture rockets cheaply. Both have completed successful sub-orbital tests, and are gearing up to be major players in the global launch services ecosystem.

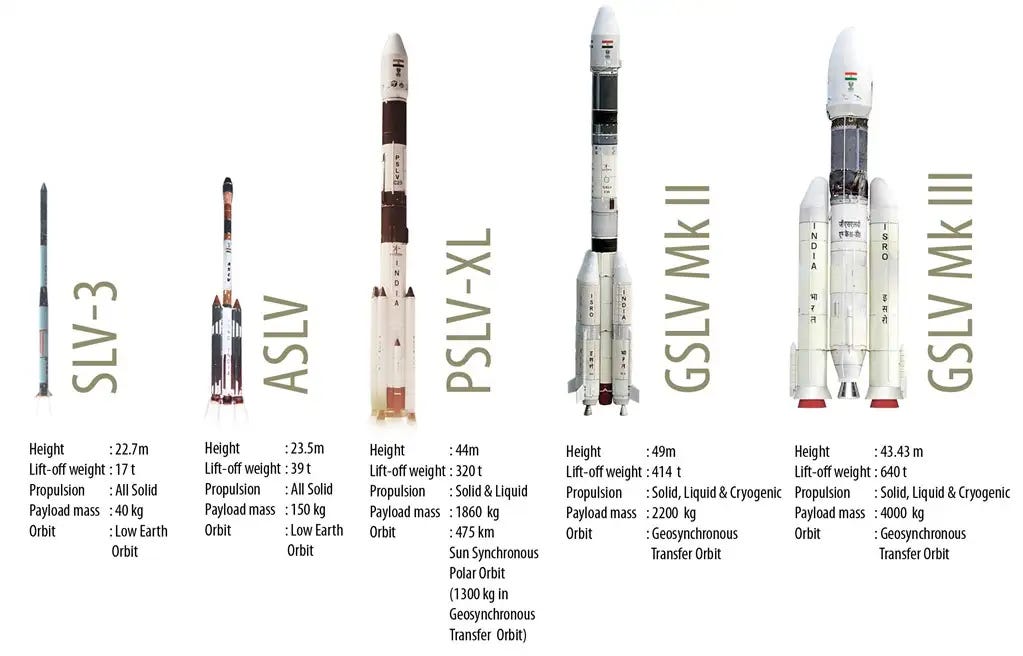

Those companies add to India's rich tradition of launch capabilities. The Indian Space Research Organisation (ISRO) has established itself as a preferred launch partner for countries worldwide, having launched more than 350 foreign satellites from 36 countries. This reputation was built on the back of its versatile rocket program, which began with the Satellite Launch Vehicle-3 (SLV-3)'s historic launch of Rohini in 1980.

While the experimental Augmented Satellite Launch Vehicle (ASLV) program followed in the mid-1980s, it was really the Polar Satellite Launch Vehicle (PSLV) that truly established India's presence in the commercial launch market. Since its first successful flight in 1994, the PSLV has completed over 50 missions with a 95% success rate, including a record-breaking launch of 104 satellites in 2017. For heavier payloads, ISRO developed the Geosynchronous Satellite Launch Vehicle (GSLV), and is now adapting to the small satellite revolution with its new Small Satellite Launch Vehicle (SSLV), designed specifically for the growing market of smaller, lighter satellites. Till SpaceX came around, ISRO was the cheapest game in town as far as per-kg commercial rates for space launches.

For Pixxel, this just means more options. The actual booking process has been streamlined in recent years. Whether it's through SpaceX's website or ISRO's commercial arm NSIL, you essentially fill out forms specifying your satellite's mass, dimensions, and desired orbit, and find a launch date/spot that works for you.

For the upcoming launch of the first three of their Firefly satellites, Pixxel chose to go with SpaceX because the numbers aligned perfectly. "The orbit fit exactly for what we needed, and for three satellites, it fits well within SpaceX's predefined volume requirements," says Kshitij. "We could utilise the space effectively, making it more cost-effective to launch all three together."

The work continues after booking too. Launch providers (in this case, SpaceX) need vibration testing reports 3-4 months before launch to ensure your satellite won't damage anything inside the vehicle. About 1.5 months before launch, they ship their satellite to SpaceX’s launch site (typically at Cape Canaveral in Florida). "Integration at the site takes about 30 days," explains Kshitij.

Every step is choreographed with precision - from charging the satellite’s batteries to final systems checks. The satellite is finally and carefully mounted into its deployment mechanism - basically a high-tech spring-loaded box - which will eventually push it into space when the spacecraft reaches its pre-ordained orbit.

"It's like getting dropped off at a station and then needing to find your own way to your house," Kshitij says about the final phase. After the rocket releases their satellite, there's a 15-minute delay before they can turn on the radio to avoid interfering with the signal of the launch vehicle. Then begins the delicate process of stabilising the satellite, deploying solar panels, and establishing communication with Earth.

Okay so what happens after it’s deposited into space?

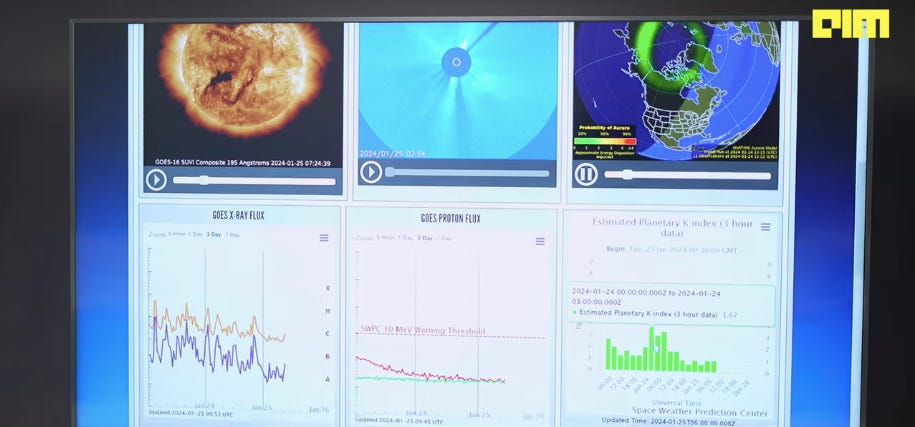

The moment a satellite separates from its rocket is when the real nail-biting begins. At Pixxel's Mission Control Center in Bangalore - a room filled with screens displaying orbital trajectories, satellite telemetry, and system status indicators - teams of engineers wait anxiously for first contact.

"It's like living on a prayer," says Manas. The satellite, freshly ejected into space, is likely tumbling due to differences in its centre of mass.

After the mandatory 15-minute radio silence to avoid interfering with the launch vehicle, the team can finally start communicating with their newborn spacecraft. To communicate with their satellites, Pixxel needs ground stations - essentially powerful radio antenna facilities that can talk to spacecraft. Because their satellites zip around Earth in low orbit at 7 kilometres per second, completing a full orbit every 90 minutes, they're only directly in the range of any given point on Earth for 5-10 minutes at a time. This means communication has to happen in these brief windows when a satellite passes over a certain ground station.

To maintain regular contact with their satellites, companies typically use a network of ground stations spread across the globe. Companies like KSAT, AWS, Atlas, Leaf Space and others provide this as a service. When Pixxel was just starting out, budget constraints meant they could only afford one station - which limited them to brief check-ins every 6-12 hours when their demo satellite passed overhead.

The first two weeks after deployment are critical. Called the Launch and Early Orbit Phase (LEOP), this period is when the satellite must transform from a dormant piece of hardware into a fully functioning spacecraft.

First, it needs to stabilise its tumbling, then unfurl its solar panels and point them toward the sun for power. The Mission Control team carefully monitors every system as it comes online - from power and thermal control to navigation and attitude determination (its orientation in space relative to Earth or other celestial objects, gauging which direction it points). "The satellite is designed to be intelligent, but not too intelligent," explains Manas. "It doesn't make too many decisions on its own - it keeps safe and survives."

For Pixxel's first demo satellite, these were particularly stressful times. "LEOP lasted two weeks - we slept everywhere in the office, beanbags, pantry, you name it…people were packed in," recalls Awais.

Each brief communication window is a frantic rush of activity. The team sends commands, downloads system status data, and makes quick decisions about the satellite's health. "If you mess up, you have to wait till the next orbit to try again. It's very stressful 10-minute periods followed by lots of analysis, followed by stressful 30-minute meetings to figure out what to do in the next 10 minutes when we have contact."

Communication with the satellite is essentially super-powered WiFi - similar frequency (2.4 GHz) but much higher power. The ground stations track the satellite based on orbital parameters provided by SpaceX and the satellite's own GPS coordinates. Over time, tracking improves as the team better understands their satellite's exact location and behaviour. Each satellite even has its own unique radio frequency signature, allowing ground stations to distinguish between different spacecraft.

The challenges multiply with multiple satellites. For their upcoming constellation of Firefly satellites, Pixxel faces a new problem: too much data. "With 3-6 satellites sending data over the same ground stations, we'll have data coming from all satellites together, then 90 minutes to analyse before the next orbit," explains Manas. It's an optimisation challenge - Pixxel’s satellites don't take images over oceans (because they’re focused on terrestrial use cases), so they use those passes to download data, via ground stations distributed strategically around the globe (courtesy of an ‘orbit design’ team that meticulously determines this type of thing beforehand).

Got it. And what happens once the data actually comes down?

Aren’t you tired of this yet??

I have a tiny bit of patience left. Let’s get this over the line.

Once a satellite is stable and commissioned, that's when Pixxel finally stretches its commercial wings. A sophisticated piece of software called the Acquisition Planning System connects with their 'order desk' at their HQ, scheduling imaging tasks based on customer requests and satellite health. Nothing is pre-programmed before launch - each command for a new data request (from a customer) goes from mission control through the ground stations to the satellite once its been properly deployed and its ready to capture images. Its a complex back-and-forth of data collection and transmission that happens 500 kilometres above our heads.

The actual imaging process is a bit like taking a panorama photo while sprinting. As the satellite zooms over Earth at 7 kilometres per second, its hyperspectral camera captures thin strips of imagery. But unlike your phone's panorama mode, each pixel in these strips contains data from over 250 different wavelengths of light. "Most satellites can only see in three colours - red, green, and blue. We're capturing hundreds of spectral bands for every single point," explains Manas. "The amount of data adds up quickly."

How quickly? A single image from Pixxel's Firefly satellites can be several gigabytes in size. The raw data comes down as a series of matrices - imagine a stack of hundreds of grayscale images, each representing a unique spectral profile. As you can imagine, this isn't Instagram-ready imagery - it needs some serious processing before it becomes useful.

"When we get the data, we need to clean it up," says Teja. "It’s because the satellite adds its own noise to the data, the atmosphere affects different wavelengths differently, and we need to account for the satellite's movement and Earth's topology."

This processing happens in stages, which they call "levels." In Level 0 (L0) the team applies basic corrections for known satellite behaviours - this is the most unprocessed form of imaging data. In Level 1 (L1) they add atmospheric corrections. And Level 2 (L2) accounts for things like terrain effects and shadows. Some customers, particularly those with extensive remote sensing experience, prefer the minimally processed L0 data to perform their own treatment. Others want the fully processed L2 data ready for analysis.

So the data goes directly straight from satellite to the customers?

Not quite. The data delivery pipeline is actually quite elegant. Firstly, the satellites themselves don't have the capacity to do any processing ‘on-board’ beyond basic compression of image data before beaming it down. The data makes its journey to Earth through the network of ground stations distributed strategically around the globe. These ground stations receive the compressed data from Pixxel’s satellites and relay it to Pixxel's facilities, where the real alchemy begins.

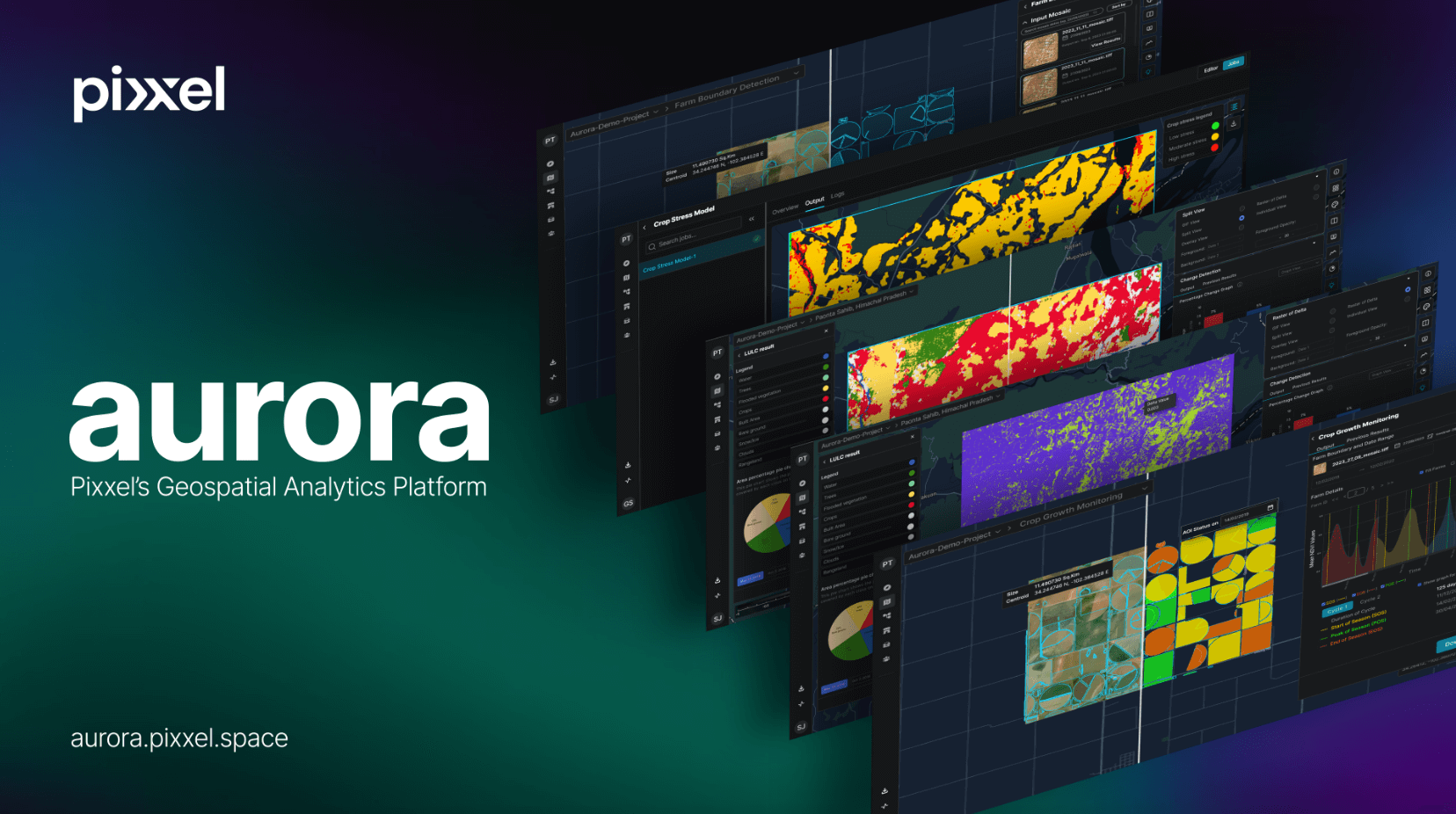

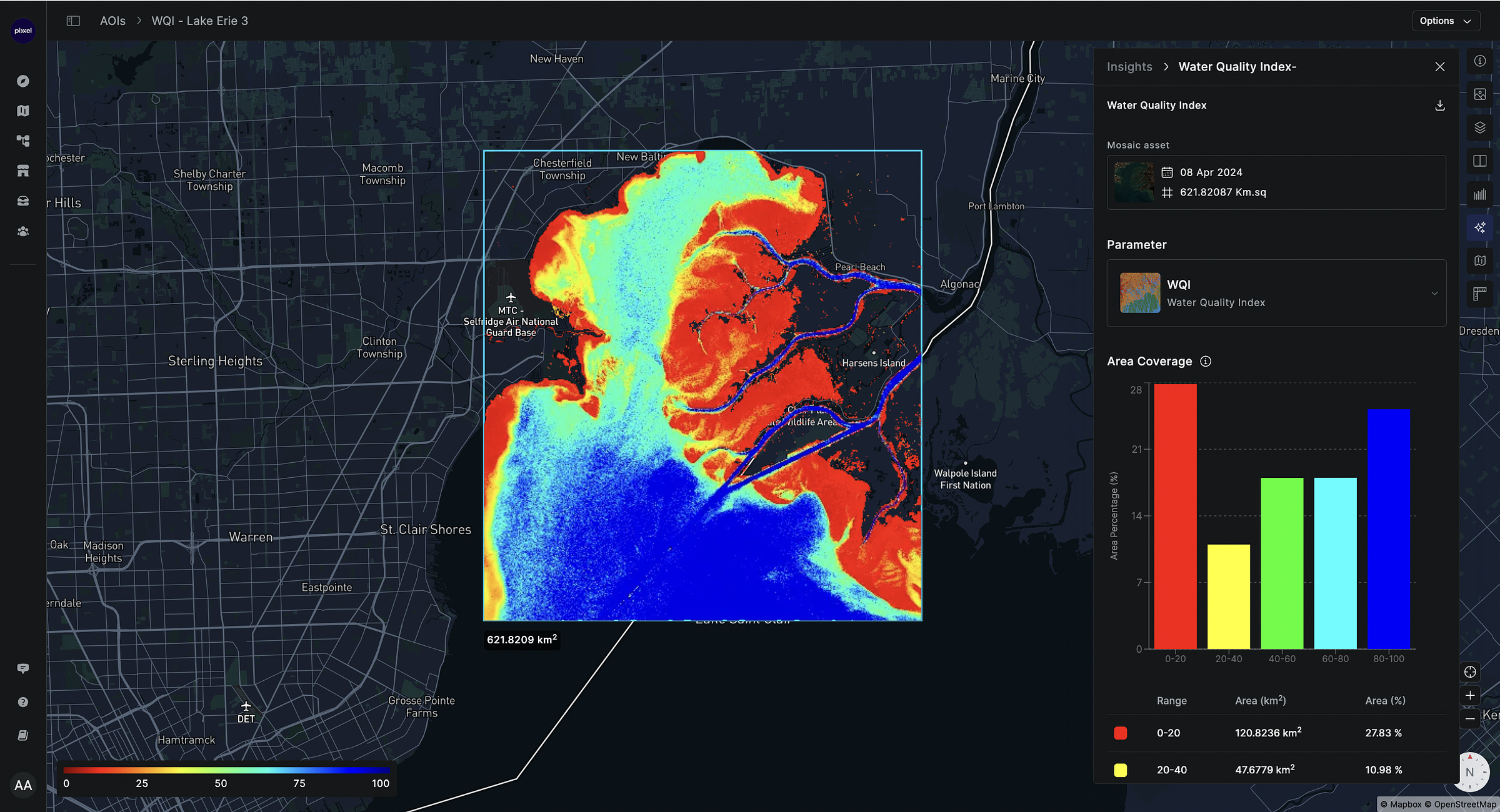

"All the heavy lifting happens on the ground," explains Teja. "The processing, colour correction, rectification - everything happens after we receive the data." The team aims to deliver processed imagery to customers within 24-48 hours of capture, with plans to achieve daily delivery once the Firefly constellation is fully operational. Customers can access Pixxel's image data via their newly launched cloud-based Aurora platform. It’s like Google Earth with a few more superpowers.

This is a far cry from how satellite data used to be shared. In the old days, you'd literally get your space images delivered on hard drives - imagine waiting for the postal service to bring you pictures from space. Today, it's all cloud-based. The data comes down through ground stations, gets processed in Pixxel's facilities, and is delivered to customers via Aurora.

Tell me more about Aurora (briefly).

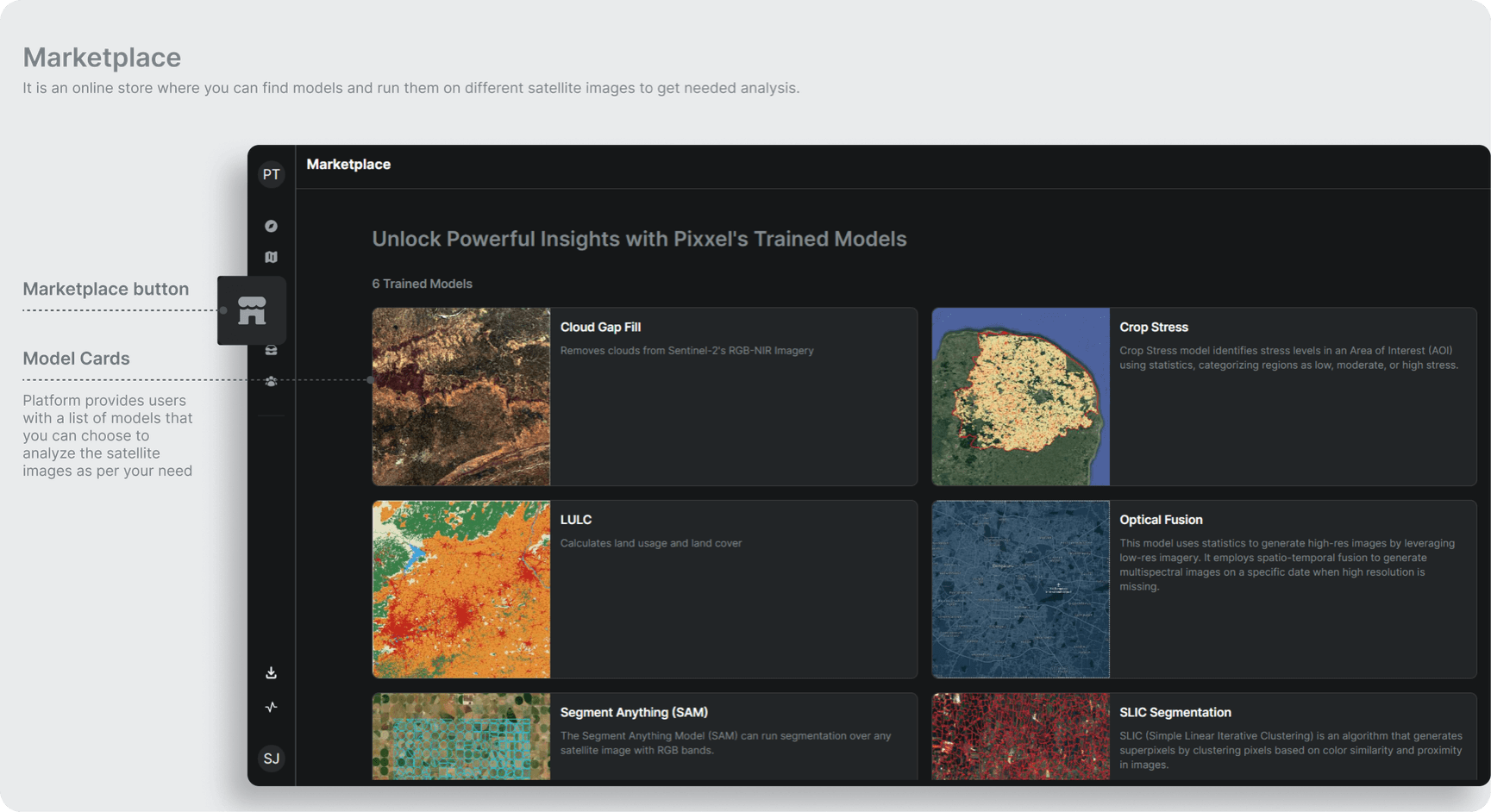

Speaking of Aurora - launched in early 2024, it's Pixxel's answer to traditionally clunky satellite imagery platforms. "Traditional GIS software can be a nightmare to deal with," says Aakash Parekh, their Chief Commercial Officer. "We wanted to build something that doesn't require a PhD to operate."

Think of it as a one-stop shop for satellite imagery - customers can draw areas of interest on a map, select date ranges, run analyses, and get results, all through an intuitive interface that looks more like a modern web app than scientific software. Eventually this will even include an AI capability that allows for sophisticated searches like "Show me crop stress in Maharashtra”, or “Show me the current water quality in this Bangalore lake”, or “Show me whether this patch of farmland has traces of harmful pesticide use.” This is an alternative to fiddling with complicated menus and software, that could open up the use of hyperspectral imaging to a wider audience.

The platform includes a marketplace of ready-to-deploy analysis models for everything from crop stress detection to mineral mapping. Users can create their own workflows through a simple drag-and-drop interface, run complex analyses with a few clicks, and share results with team members. It's the kind of tool that makes space data accessible to business analysts, not just remote sensing scientists.

They can log in, view available imagery, and place orders for new captures. The platform includes tools for analysing the hyperspectral data, turning those hundreds of spectral bands into actionable insights about everything from canopy health to algal blooms to pollution levels.

"Different customers need different things," explains Awais. "A mining company might want specific mineral signatures. An environmental agency might be tracking carbon emissions. Governments might want something else. Aurora gives our customers the ability to extract bespoke insights and analysis from the same images.” The data typically arrives in a cloud-optimised GeoTIFF format - a far cry from the old days of shipping hard drives around. “We will even be able to do this via API going forward,” says Aakash.

This is where Pixxel's full-stack approach pays off. Because they control everything from the camera design to the final data delivery, they can optimise the entire pipeline to cater to the precise needs of customers in different countries, sectors, and with different use cases, all from the same satellite, the same camera, and the same platform.

Phew. Okay last question, are there any, like, laws that govern this stuff? Does Pixxel (or any satellite operator) need permission to do any of these activities?

Turns out, launching cameras into space requires quite a bit of paperwork. Satellite operators need two critical licenses: a spectrum license (which is like calling dibs on specific radio frequencies to communicate with your satellite) and an imaging license (which dictates what you can photograph and at what resolution). In India, these authorisations come through INSPACe, while in the US, it's split between the FCC for frequency and separate authorities for imaging rights.

"Each country has its own standards," explains Awais. "We need to do KYC on our customers, avoid working with sanctioned countries, and in case of national emergencies, the government can direct our imaging activities."

What's fascinating is that there's no single space traffic controller coordinating all this orbital activity. Instead, there's the International Telecommunication Union (ITU) - a body that helps coordinate but can't actually enforce rules. It's more like a galactic diplomacy club where countries agree to play nice. The country licensing a satellite takes responsibility for its behaviour, which includes ensuring the satellite is trackable from Earth to avoid adding to the growing problem of space debris. "Your satellite needs to be big enough to be tracked from the ground," explains Kshitij. "Companies have been fined for launching satellites too small to monitor." After all, with over 13,000 satellites now circling Earth (more than half of which are SpaceX's Starlink satellites), keeping track of what's up there has become critical for everyone's safety.

Nice. Are we…done?

Yes, we’re done. Thank you for sticking around. Now you and I know the same amount about satellites and space.

To recap where we were, the Pixxel team was in the midst of regrouping after the failure to launch their first Anand satellite in February 2021. They took the decision to build their ‘second’ demo satellite in-house (vs relying on an external vendor), and geared up for another attempt at making it to space in 2022.

Now back to the story.